Congratulations to the City of Pickering for holding the Guinness World Record for the longest enclosed pedestrian bridge in the world.

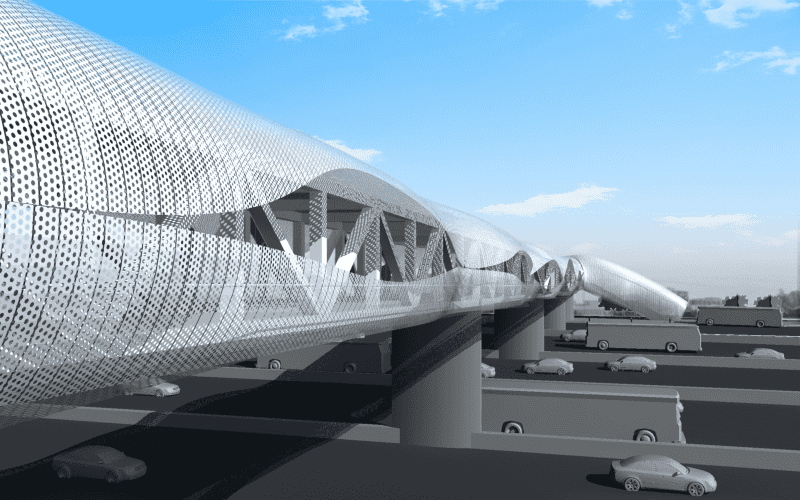

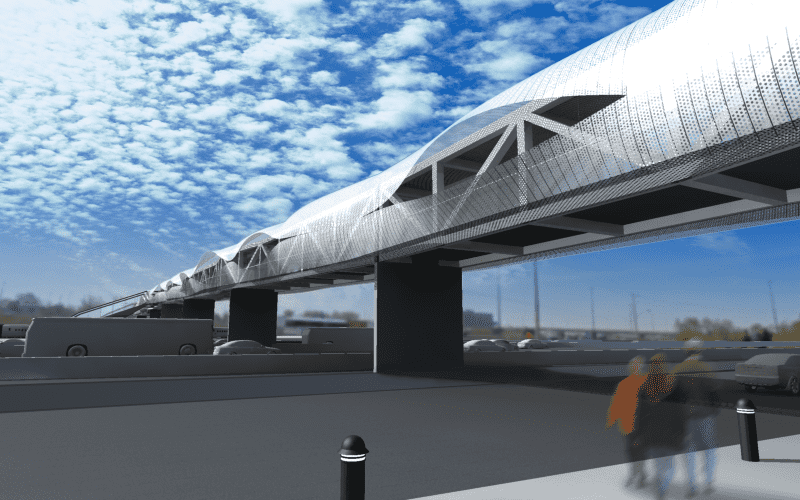

The Pickering GO Pedestrian Bridge recently received a record from the Guinness World Records for the longest enclosed pedestrian bridge in the world. Located in the City of Pickering, 32 km east of downtown Toronto, the 250-meter bridge makes its way across 14 lanes of Highway 401, six live rail tracks and a two-lane municipal roadway. Completed in 2018, the bridge features an iconic architectural structure that is highlighted with around 300 LED lights at night.

To accommodate the pedestrian traffic and connect Pickering station to the region’s largest shopping mall and local college, a bridge project was undertaken by multiple levels of government and the provincial rail agency in 2011. The project experienced multiple project phases throughout the years of construction over the busiest highway in North America.

An unparalleled innovation in architectural design and materials

The pedestrian bridge is the first of its kind in terms of architectural design: a standard truss-based steel structure with concrete flooring and a membrane-on-steel-deck roof, the bridge’s interior has customized glazing that provides a comfortable interior environment. It is also the first bridge to be covered in a highly specialized perforated aluminum sheeting (cladding) called Kalzip.

The Kalzip material allows light penetration and ensures visibility from both inside and outside of the bridge. Utilizing a passive ventilation approach, the Kalzip material resists solar gain, easily sheds snow and ice (before accumulating), and reduces wind-loading. Most importantly, the material gives the bridge a progressive look that beautifies the area around it. It is practical and gorgeous all at the same time.

An unprecedented challenge in fitting custom-made structures

The installation of the interior glazing and the Kalzip cladding presented a unique challenge for the engineers and contractors involved. Both the interior glazing and the Kalzip cladding were custom manufactured. The sophisticated structural design of the Kalzip cladding came with an intricate perforation pattern and a unique proprietary connection. Since the Kalzip was cut and form-rolled on-site into compound curves, each individual sheet must be cut extremely accurately to be mounted successfully. To address the challenge, Applied Precision 3D was requested to provide high-accuracy 3D data for the areas where the materials were to be installed.

How LiDAR 3D scanning ensures better fit for installation

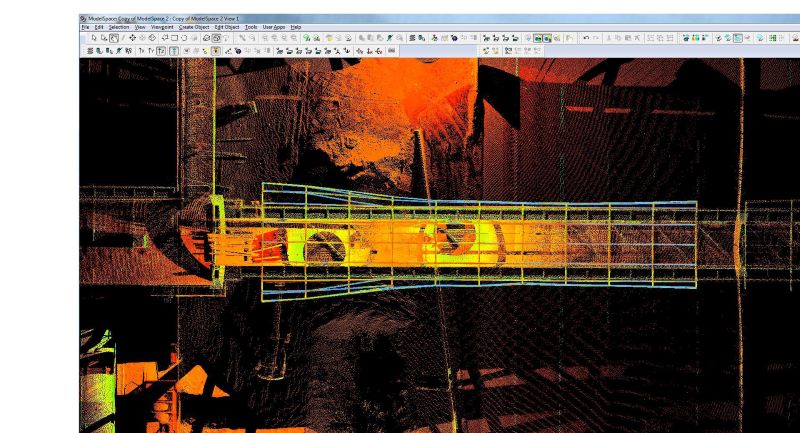

Having reviewed the tight dimensional requirements and sophisticated design, and made reconnaissance visits to the site, the Applied Precision 3D team decided to implement LiDAR 3D scanning to produce “as-built” data for the installation.

The LiDAR 3D scanning of the glazing openings and the Kalzip cladding produces digital templates that can be used to adjust drawings and ensure a better fit. If there were discrepancies, then the contractor was able to make adjustments, thereby minimizing scrap from test-fitting and installation. Additionally, survey targets were installed throughout the scan scenes to help alignment from scans and achieve the required 3D measurement accuracy.

Once the data was collected through LiDAR 3D scanning, the team post-processed it and ran an auto-alignment software tool to generate a uniform point cloud. Through the reverse engineering CAD software, the point cloud was transformed into a model of construction elements of interest requested by the contractor. This was the ‘as built’ structure.

Critical 3D measurements in Toronto’s mass transit infrastructure expansion

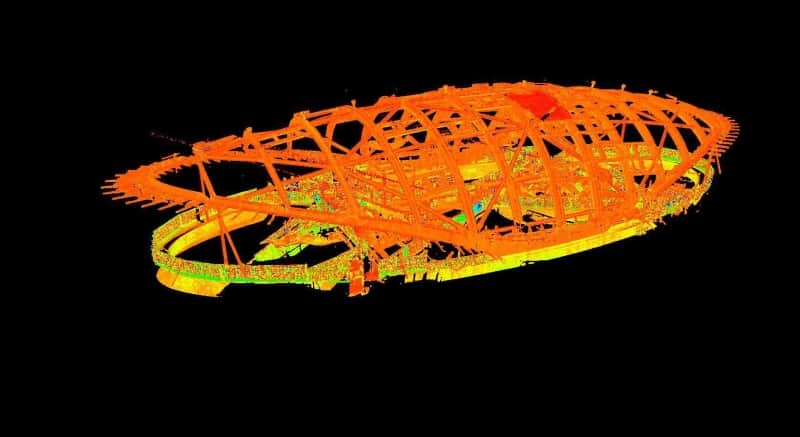

As an important contributor to Toronto’s expanding transit infrastructure, Applied Precision’s 3D measurement and 3D modeling expertise played a key role in the expansion of the TTC Yonge-University Line 1 to Vaughan. These involved much more complex and progressive designs, fabrication challenges, and site construction difficulties that the TTC had not faced in the past.

To install custom glass and Kalzip on the roof curves of the TTC stations, most notably, the Highway 407 station at Jane and Highway 407, the Applied Precision 3D team used advanced LiDAR 3D scanning in conjunction with 3D laser trackers to collect critical measurements needed to verify the unique architecture. 3D modeling of the ‘as-built’ conditions was completed at various stages. Using advanced 3D technology and 3D inspection software, the Applied Precision team checked and modeled the complex structures of each station to ensure installation fitment. This involved the core steel structures, concrete structures and features for the installation of custom glass and Kalzip material on the roof.

Our Team of 3D metrology and construction inspection experts here at Applied Precision 3D has been called upon many times over the years to help solve difficult and complex 3D construction problems, commented Robert Bell, Founder and President of Applied Precision 3D.

I am proud of the dedication and problem solving expertise that was applied by our Team to each challenge from Toronto’s iconic Union Station, Eglinton Station, the new Vaughan Metropolitan Centre Subway station to the new Guinness record holder; the Pickering GO Bridge.

We certainly look forward to supporting the on-going development of the Greater Toronto Area’s transit infrastructure in the coming years, added Bell.

Benefits From Use of LiDAR in BIM Methods

Without 3D scanning there would be no other cost-effective method to get the Kalzip to accurately fit on the first go. Test-fitting without the ‘as built’ CAD model, referred as “trial and error” approach, would typically lead to a high scrap rate and project delays.

Large scale 3D scanning offers the capability to capture ‘as built’ information, at a cheaper cost than test-fitting on site as adjustments to the drawing on site and achieve proper installation the first time. Buildings of various types of materials can be digitized through LiDAR 3D scanning to provide comprehensive 3D data to architects, engineers, and construction workers.

Applied Precision 3D has more than 20 years of experience applying high-precision optical 3D metrology principles to many challenges including institutional and commercial buildings. Our expertise, combined with today’s advanced 3D laser digitizing technology, offers speed, accuracy, and reliability to meet demanding architectural design and construction challenges in mass transit, custom glass installations, piping layouts, plant layouts, historical buildings and heritage sites and new build construction.

Get a quote for your project today.

Source: LiDAR Magazine